This article is relevant if you are wish to use NetSuite to track in-transit inventory and automate landed costs where inventory moves from a product manufacturer / supplier through a series of logistics companies to the ultimate warehouse.

Background

Many of our clients are in the distribution business while utilizing manufacturing by suppliers in the Asia Pacific Rim. The common business model is to design products locally, have goods manufactured in Asia with customer distribution worldwide via a network of warehouses often handled through third party logistics (3PL) companies. To keep freight costs low, most of our clients use sea faring cargo vessels to get goods across various oceans ultimately to forwarding companies that will move inventory via trains and trucks to the inventory warehouse. The movement of goods involve tracking delivery information (logistics) including accounting for an array of (landed) costs that are beyond basic purchase order manufacturing cost.

Some of the key challenges in this model include accounting for the lead time between when a manufacturer order is placed and the time it will take to arrive in the inventory warehouse to be available for customer distribution. Because goods move relatively slow from the manufacturer, a significant amount of inventory can be tied up in-transit and often is “On-the-Water” as it makes its way to the ultimate warehouse. Collectively, logistics are all the mechanics need to track, protect and care for the movement of goods. Logistics costs, such as freight, insurance and duties, are incurred as goods make their way to the warehouse. In NetSuite speak, these logistics expenditures are called landed costs and should increase the unit inventory cost. NetSuite provides a capacity to capitalize (add) landed costs against purchase order item receipts to increase unit inventory cost as it sits in the warehouse.

Almost without exception, and out of necessity, I see that my new and prospective clients have built elaborate spreadsheet tracking systems to keep on top of their inventory logistics. In my mind, any home-grown spreadsheet tracking system is a candidate to be replaced by the NetSuite platform (assuming the value can be produced to move to new software). NetSuite’s basic architecture to track various elements of this logistics model are in place. Yet, in my assessment, the structures are disjointed and demand a fair amount of manual practices in record upkeep. Thus there is an opportunity to “bring it all together” so that the information flow is streamlined and easy to manage.

Introducing Prolecto Freight Container & Landed Costs

We solved these challenges and effectively produced a bundle to help our clients be more competitive. The key to solving this is to build on the following constructs:

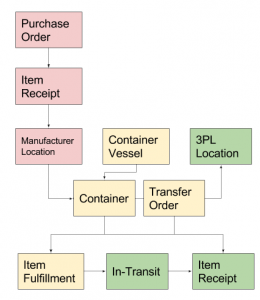

Virtual Manufacturer’s Warehouse and Inventory Transfer

First, we need a way to distinguish when goods are finally manufactured but ultimately moved into the logistics realm. This is achieved by creating a NetSuite virtual manufacturer’s warehouse location record. The idea is that as goods are manufactured, we accept delivery, via item receipt, into the conceptual warehouse. Thereafter, we leverage NetSuite’s built-in inventory transfer mechanism to move the goods from the virtual manufacturer’s warehouse to target real warehouse. By doing this, NetSuite will automatically create Inventory In-Transit as a NetSuite Transfer Order effectively creates related Item Fulfillments (move goods away from the warehouse) and related Item Receipts (move goods toward a warehouse). When worked as a practice, there will never be goods in the virtual warehouse — it’s simple a holding area to get goods in-transit. See related image for conceptual linkages.

The key to making this work is to identify the ultimate warehouse destination at the time the purchase order is issued. As far as NetSuite’s native capacity is concerned, the goods are going to be received in the virtual manufacturer’s warehouse which is an important milestone, but incomplete as far as the inventory journey.

Freight Container and Cargo Vessel Tracking

Typically, goods are organized into freight containers as they move to the target warehouse. Many times, we see our clients request a large manufacturing production which is represented by a single purchase order. Yet, the goods are going to ultimately land in different warehouse locations. In our Freight Container System, as the manufacturer effectively creates an Advanced Ship Notification (ASN) document (often in email or spreadsheet form), a number of freight containers are identified to organize how inventory is in-transit to the ultimate warehouse. Each freight container may have one or more inventory goods (SKUs) in them; generally, a container will hold goods until it reaches the ultimate destination where all items are then received into inventory stock. Thus, the freight container is an important logistical construct. NetSuite offers no native construct.

Our model allows for the definition of one or many freight container records, the goods that are within, the status of each container, such as “At Origin Port”, “At Sea In Transit”, “At Landing Port”, “In Transit to Destination Location” and finally “Received at Destination Location”. Each status offers expected and actual dates of key logistical milestones. Many times, multiple freight containers may be involved in a single manufacturer production and collectively, these containers end up on a sea-faring cargo ship. We provide a mechanism to define a Vessel that allows all the freight containers to move together as a group as they cross oceans. The benefit of this grouping is that as the status of the expected vessel landing is updated, the related freight containers can inherit the logistical values keeping record management minimal and modeling the reality of physical goods movement.

Freight Forwarder Container Tracking with Landed Costs

After a freight container lands into a sea (air) port, each container may now start to move toward the ultimate warehouse location. At this point, the container is now moving independently of other related containers and thus logistically, separate tracking is required. Further, as the freight container has been moving towards its final destination, true logistical costs are accumulating. Depending on the destination warehouse, logistical costs may naturally vary. Fortunately, NetSuite appropriately tracks inventory costs based on warehouse location which means your inventory cost can vary depending on where it is located, even if the original manufacturing costs started out the same.

I have written articles in the past about Landed Costs. See Offer: Superior NetSuite Landed Cost Practice with Late Vendor Bills and Offer: Superior NetSuite Landed Cost Practice with Late Vendor Bills to learn about the practice that uses estimates to streamline the information flow. In our Freight Container bundle, we allow the definition of estimated landed cost by location so that once the inventory is received by the final warehouse, we automatically burden the inventory cost by automating NetSuite’s built-in landed cost feature. The automation will capitalize inventory cost by location thus giving management a truer accounting of inventory and ultimately product margins once sold.

Inventory Logistics Visibility

Finally, once you have all this information properly tracked with vessels and freight containers, it’s important to be able to understand where inventory is (or has been) in real-time fashion. Due to the number of information record constructs involved, and because NetSuite’s saved search capacities are limited to single join (see Supercharge NetSuite Advanced PDF/HTML Templates for reference), it is a challenge to produce a single query that makes it easy to see the item’s full logistics story. Thus, we leverage SuiteLet technology to “pull it all together” to connect the original purchase order, through the transfer order, through warehouse item receipt. See related screen shot.

Refine the Freight Container to Fit Your Requirements

Like all the things we offer in our professional services firm, we are not in the NetSuite Software Product business. In contrast, we are NetSuite accounting and platform innovation experts and our bundles are reflections of our superior capacity to conceive, design, develop and implement NetSuite driven business solutions. Our commitment is to see our client’s succeed and our offer is intellectual talent. The bundles we offer represent a “kickstart” to get you to your goal. Since your success is our primary importance, we work with you to confirm your requirements will be met — which might mean we may suggest that the software bundle be refined as we help you with an implementation. Should you have a requirement where you believe we can help, let’s have a conversation.

See Related Articles

- Best Practice: NetSuite Driven International Drop Ships / Direct Import Flows

- Drive Automated NetSuite Transfer Order based Landed Costs

- Learn NetSuite Landed Costs Fundamentals

- Learn How To Automatically Apply NetSuite Landed Costs from Purchased Freight

- Overcome NetSuite’s Inbound Shipment Over Receipt Challenge

- Finally: Capitalize NetSuite Inventory Costs with Item Consumption Landed Costs

- Global Logistics Practices for NetSuite Driven Distribution Companies

Could you please help me to create a KPI Meter for Revenue Versus Quota in Dashboard?

Marty, this looks really nice. But the requirement we often run into is for one container with many PO’s in it. It looks like this solution would not work for companies with that requirement, would it?

Hi Hollie,

Absolutely. The model can support a single freight container that can be referenced by many purchase orders and their respective item receipts.

Marty

Hello Rajitha,

Your question is off-topic from the article. I recommend you reach me at https://www.prolecto.com/services/innovations/

Thanks for this Marty!

Would this bundle include the ability to calculate landed costs by CBM?

Hi Vincent,

We could model that as we have complete control over the algorithm. For now, we assume container sizes are standard. But it would be simple to add that dimension.

Marty